The launch of our latest phase of Automated Hanger System (AHS) marks a leap forward in Operations efficiency at RT Knits. This AHS now seamlessly extends to Packing section after previously connecting Sewing and Ironing lines. The system enhances our Garment Mill operations and productivity through:

- Optimised material handling

- Improved transparency

- Enhanced consistency

- Minimised errors

- Less waste generated, more sustainability

By automating repetitive and labour-intensive tasks, we have strategically empowered our workforce for more impactful roles.

This project aligns with our guiding principles for improved productivity at RT Knits:

![]() Automation

Automation

![]() Logistics Automation

Logistics Automation

![]() Digitisation

Digitisation

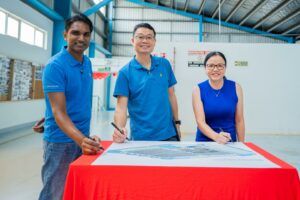

The implementation of RT Knits Automated Hanger System, owes its success to a collaborative effort of Make Up, Packing, Engineering and Maintenance teams. The launching ceremony took place on Monday, November 6th.